EXAKT Advanced Technologies GmbH

Booth number: H4.E81

www.exakt.de

About us

EXAKT Advanced Technologies has been an established global leader in the manufacturing of precision three roll mills and cutting and grinding equipment for decades.

Our devices and technologies are in use across a variety of industries and applications worldwide. From R&D to essential parts in industrial production and quality control - we offer customised solutions for every environment always providing reliable precision.

Top quality »Made in Germany« has been manufactured in our factory in Norderstedt near Hamburg for 75 years. From our two plants we export EXAKT technologies internationally and today our machines can be found in more than 80 countries around the globe.

Address

Robert-Koch-Str. 5

22851 Norderstedt

Germany

E-mail: nicole.zeh@exakt.de

Phone: +49 40 5295600

Internet: www.exakt.de

Contact person:

Lars Dettmann

Head of Sales

E-mail: lars.dettmann@exakt.de

EXAKT 80E PLUS Three Roll Mill

Based on a high-precision, rock-solid mechanical design combined with a state-of-the-art digital electronic control system, the EXAKT 80E PLUS offers all-in-one dispersing and analyzing functionalities:

Real-time analysis of the dispersion process

Monitor and optimise process settings in real time

Record process settings for comprehensive documentation

Intuitive and easy operation

EXAKT 120EH-450 e-con

The EXAKT 120EH-450 has been the dependable solution for customers across a variety of industries for over a decade. Particularly, the electronic pastes and solar sectors swear by its precise and reproducible production capacities:

- Precisely set all relevant processing parameters via the user-friendly display.

- Program and store recurrent production processes and parameters for documentation and subsequent analysis.

- The machine also provides a temperature control feature

EXAKT 50 PLUS

EXAKT 50 PLUS – the new standard for laboratory applications. Our newest model offers significantly higher performance combined with a user-friendly design and operation. Higher torque allows for precise dispersion – especially for high-viscosity materials. One-handed adjustment of gap widths guarantees excellent and reproducible product fineness. Effortlessly set the roller speed using the user-friendly membrane touchpad. High-quality roller surfaces (chrome or aluminium oxide) and the appealing stainless-steel exterior housing allow quick sanitary cleaning.

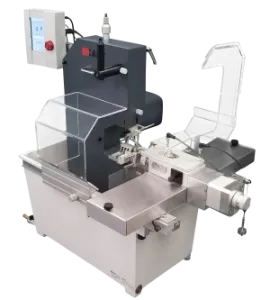

EXAKT 300CP

The Exakt 300 diamond band saw is specifically designed for cutting a wide variety of different materials and material composites. Its smooth coplanar cuts, depending on the diamond bands used, meet even your highest requirements for roughness values. additionally, the standard coplanar feed and tailstock allow for a variety of sample holders making it easy to attach a large variety of sample shapes, sizes, and textures securely.

Safe: almost no cutting risk for operator

Use for a wide variety of different materials and composites

Achieve excellent roughness values in one step with very little cutting loss

Minimal thermal loading of sample

Compact size and space-saving design

User-friendly small control unit with colour display

Automatic sample positioning