kolb Cleaning Technology GmbH

Booth number: H4.E83

www.kolb-ct.com

About us

YOUR Process Supplier

For over 35 years, kolb has been delivering cutting-edge cleaning systems that combine innovative technology with process-optimized detergents and intelligent, software-driven process solutions – designed to meet the economic and ecological demands of today and tomorrow.

Achieving optimal cleaning results requires more than just the perfect match between detergent and cleaning system. The decisive factor is the process itself – the precise coordination of every component involved in the cleaning operation.

Our expertise in mechanical engineering and chemical development for solving all cleaning tasks in the field of electronics production makes us the only supplier in the world that can deliver the complete process design consisting of a qualified system, ideal detergents and individually programmed process software from a single manufacturer.

Address

Karl-Arnold-Str. 12

47877 Willich

Germany

E-mail: info@kolb-ct.com

Phone: +49 2154 9479-99

Internet: www.kolb-ct.com

DSM-164, DLF Tower, Shivaji Marg

110015 New Delhi

India

E-mail: rohit.sikka@kolb-ct.com

Phone: +91 98105 43578

Internet: www.kolb-ct.com

Contact person:

Rohit Sikka

Technical Sales & Support India

E-mail: rohit.sikka@kolb-ct.com

Phone: +91 98105 43578

Products & Services

kolb cleaning systems deliver solutions for all of the high demands which are made by the electronics producing industry, ranging from highly sensible ultra fine cleaning e.g. of DCB hybrid substrates and PCBs to heavily contaminated flux management systems or basic production tools - from smaller devices to large scale plants, from single use to full flexible highend cleaners.

kolb develops and produces cleaning detergents specifically for the electronics industry for over 35 years, especially adapted to the varied requirements of this business. Our products are created from the customer's needs - current and fast.

AF 20 | Maintenance Cleaning

Fully automatic one chamber system for all maintenance cleaning tasks

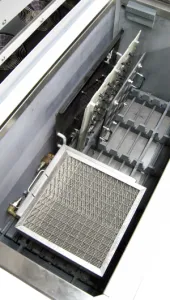

The kolb AF-series offers rugged state of the art systems for maintenance cleaning working with the aqueous with AirFlow® technology, the thorough and environment sound turbulence air in immersion cleaning process developed by kolb. This technology differs from common spray-in-immersion applications, as the goods to be cleaned here are actively submerged everywhere by the cleaning fluid which is swirled with compressed air. It guarantees a permanent all over active flushing without dead spots so that every contamination is fast and efficiently cleansed off.

kolb AF20 is a state of the art immersion cleaning system with ClosedLoop water reprocessing. It cleans components of flux management systems (cooling units, filters, heat exchangers, containers/plates) of virtually all manufacturers as well as the parts, milled parts or die cast components from flux, condensate, oil, dust, grease using the economic and environmentally friendly AirFlow® technology.

PSE 300 HD | Stencil Cleaning

Fully automatic economy basic screen and stencil cleaning system

The kolb PSE stencil cleaning systems are a quality series of advanced cleaning machines, which focus on all essential criteria for a qualified screens, stencils or misprints and scrapers/squeegees cleaning process and therefore stand for attractive purchase prices. The systems of the PSE 300-series offer extremely compact machines with PowerSpray® technology. They are perfectly applicable for small and medium sized companies and smaller quantities as well as for mass production plants where a cleaning system is placed to each printer. The kolb PSE MV8 TWIN is a single chamber PowerSpray® system for the thorough cleaning of two stencils (in one cleaning cycle), which provides excellent cleaning results in a short cycle time.

The entry model to safe and efficient fine cleaning: kolb PSE 300 HD is an extremely compact cleaning system, engineered and manufactured in Germany. Perfect for small and medium businesses with moderate daily cleaning requirements or for large companies with several printers where to each printer a single screen/stencil cleaner is installed. PSE 300 HD is a system for optimum cleaning of stencils, misprints and solder carriers, nowadays a prerequisite for reproducible quality and for low failure rates and thus high customer satisfaction. PSE 300 HD is ideally suited as a cost-effective system especially for the easy, quick and thorough cleaning of coating residues from carriers protected with the innovative kolb CarrierSeal® sealing.

PSE MH7 | Tools & Maintenance Cleaning

Fully automatic XL tools and maintenance economy cleaning system

The kolb PSE MH-series offers all-round systems for nearly all requirements of maintenance cleaning from flux, oil, dust and grease for carriers/masks, ESD boxes, PCB magazines, pallets, machine parts and other small parts (for example, turning and milling parts). The systems are very compact, energy saving and well equipped in their basic version.

PSE MH7 is an "allround" economy cleaning system for tools and maintenance cleaning with an XL process chamber. PSE MH7 is a German engineered and manufactured machine with ClosedLoop water reprocessing and a two-tank and up to three circuits configuration which ensures short cycle times and makes this system a perfect choice for tools cleaning in electronics production.

MultiEx® N7-TS | Detergent for Stencils, Screens & Misprints

Regenerative stencil cleaning and rinsing detergent

MultiEx® N7-TS (as ReadyMix or concentrate) is a broadband neutral cleaning detergent and provides excellent results for cleaning screens and stencils as well as for misprints and stencil undersides cleaning in screen printers. The rinse suitable detergent can be used in water-free systems/processes. MultiEx® N7-TS cleans particularly pastes, dust, fats, oils and (conditionally) adhesive and flux. Depending on cleaning task also suitable for PCBAs, solder carriers, solder pallets, ESD boxes, PCB magazines. The cleaner is formulated as a single-phase agent and thus the cleaner remains stable in itself without permanent agitation.

ContraFlux® FM | Filter & Tools Cleaning

Alkaline multifunctional aqueous tools cleaning detergent

ContraFlux® FM is an aqueous alkaline special cleaner for maintenance cleaning especially of condensate management systems specifically from condensate and rosin. It is ideally suited for the quick and thorough cleaning of condensate traps, filter sheets, coolers, cyclones. Depending on the cleaning task also suitable for solder frames, solder pallets, ESD boxes and PCB storage magazines. ContraFlux® FM can absorb flux up to 20 percent of its volume. This means a very long service life and thus high cost efficiency. Ideally suited for the external cleaning of piping and cyclones.

-thumb.webp)