Pfarr Stanztechnik GmbH

Booth number: H4.F82

www.pfarr.de

About us

Ever since the establishment of PFARR Stanztechnik in 1982, we have been committed to a high level of reliable quality coupled to flexibility and maximum reliability. This corporate commitment is the basis for our excellent reputation in so many countries.

Our production range covers precision metal preforms, strips and foils for diverse industrial applications; whereby solder and braze for the electronics, microelectronic and automotive sectors represent our core business.

PFARR Industrie Vorrichtungsbau e.K. (www.pfarr-piv.de) provides top-quality tooling, enabling us to meet and exceed specific customer needs with maximum flexibility and efficiency: this member of the Pfarr family of companies designs and builds for us punching and bending tools in every conceivable design and dimension.

Maximum vertical integration coupled with specific technical expertise and many years of experience form the basis of top-quality products: “Made in Germany” at the right price. The total satisfaction of our business partners, whether suppliers or customers; that is the goal continuously motivating the employees of PFARR Stanztechnik.

Address

Am kleinen Sand 1

36419 Buttlar

Germany

E-mail: paula.zitzmann@pfarr.de

Phone: +49 36967 74727

Internet: www.pfarr.de

Contact person:

Anton Turco

Head of Sales

E-mail: anton.turco@pfarr.de

Phone: +49 175 1840295

Prannoy Johnson

Process Engineer

E-mail: prannoy.johnson@pfarr.de

Products & Services

High purity soft solders

High purity braze solders

Layered materials

PFDS400®

Diffusion Soldering

Wireguard®

Plastic stamping

Targets

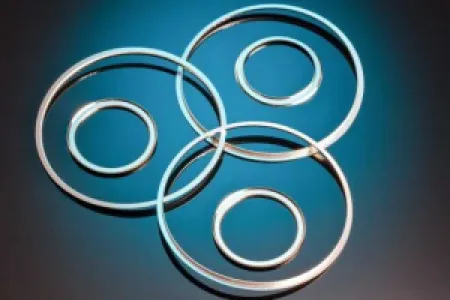

Landal-Seal®

High purity soft solders

Our soft solders are characterised by their excellent solderability. Our general range covers the following solder compositions (melting points from 115°C – 450 °C).

High purity braze

Our braze materials are alloyed under vacuum, free from oxides, resulting in excellent wettability. The following represent our standard alloy range (from 450 °C melting point).

Layered materials

Ever-increasing demands on their geometry and resilience have pushed preforms of monolithic materials towards their limits. Roller laminated materials can provide the answer: sheets of different materials and solders are combined to produce completely different properties.

Plastic stamping

Precision stampings in plastics are an important part of our product portfolio. We can work with any polymer material exactly to your wishes. We already punch an enormous range of plastics.

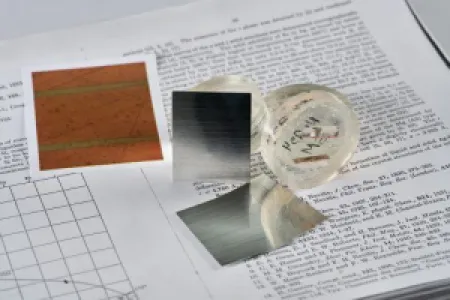

Targets

Thin, precious metal coatings in ultra-high purity can be applied to numerous substrates using vapour deposition. The process requires high-purity targets available from Pfarr Stanztechnik. Vapour deposition is used in many electronic products, in optics and medical technology as well as in measurement and control technology; whether onto glass, mirrors or solar cells.

PFDS400®

Under the brand name PFDS400® (Preform-based diffusion soldering technology for high temperature applications: above 400 °C), PFARR Stanztechnik offers a revolutionary multi-layer solder range. Using conventional soldering processes with short dwell maximum peak temperatures of 250 °C, these new composite materials produce complete intermetallic phases (IMPs) in the Lead-free solder junctions without pressure or reheating. The resulting structure exhibits a re-melt temperature of over 400 °C.

The composite materials are made from multi-layer systems of tin-based, lead-free solders, together with high melting point metals such as Copper (Cu). The overall thickness ranges from 50 μm to 300 μm. Other alloys and dimensions are available on request.